Hayley Devlin LLB

Legal writer and former solicitor

My invention is a wheelchair wheel cleaner that cleans and dries the wheels of power wheelchairs. It is designed to help power wheelchair users of any disability and is largely aimed at schoolchildren, but calculations, simulations and tests have been carried out for an adult of average weight (83.6kg), using a standard power wheelchair (250lbs or 113.398kg).

I have chosen to design a product to help people with this disability because I have done a lot of research into how wellbeing is holistic and how physical disability, mental wellbeing and independence are all linked. I found that according to future learn, “people with disabilities may be at greater risk of poor general health and wellbeing”. This may be because they have difficulty in accessing healthcare and may face many challenges both socially and physically in their lives, which can damage their confidence.

To improve this statistic, it is important to allow young disabled people to take part in “decision and choice making”, which means allowing them to carry out tasks for themselves and not become too dependent on other people if it can be avoided. The Futurelearn article also suggests that health should be looked at holistically. Hence, any methods of improving a disabled person’s mental wellbeing can also be vital to their physical and social wellbeing. Also, as discussed earlier, mental wellbeing can often be affected by decision-making and dependence on other people.

Therefore, if someone’s mental wellbeing is negatively affected by their physical wellbeing, it is important to improve it in other ways, such as through giving them greater independence. The NDIS (National Disability Insurance Scheme) independent advisory council which promotes the independence of people with disabilities have said that they should “maximise opportunities for participants to maximise their independence” in order to provide people with disabilities with increased confidence.

According to SEN magazine, assistive devices are one of the ways to achieve this as they provide greater independence to people with disabilities and allow them to carry out tasks they may otherwise struggle with. These tasks can include going to school and being able to work, so can hugely impact the person’s economic potential. From this source, it can also be inferred that without assistive devices, people with disabilities can be prevented from working well or even at all, and they may not reach their full potential. [4]

The inspiration for my idea came from a second-year school of engineering design module from my university. It was set by a member of staff from Sherbourne Fields School for disabled children. It said:

“Sherbourne Fields is an all age special school for pupils with a broad spectrum of needs including physical disabilities, medical conditions and learning needs. The school’s population is wide ranging and diverse. As such, there are many potential challenges the school could pose, and the following are the two most suitable:

Wheelchair Trailer – the school has a “forest school” area where the children go away from hard paved areas to experience adventures in the forest. Children who are electric wheelchair users participate in this learning activity, but in order for them to be able to fully participate they need to help bring tools & other equipment to the forest school. As such, we would like a small trailer attachment for a child’s electric wheelchair, suitable for off-road use.

Having used the wheelchairs in the “forest school” the wheels are very muddy. This problem is exacerbated by the mud guards. It would be beneficial to have some means of easily cleaning the wheels, and ensuring they are then dry enough to go into the school without making too much mess. Ideally the children should be able to operate/activate the cleaning device themselves.”

This describes the “forest school” which they use to try to involve all the children, including wheelchair users, so they feel they are participating fully. However, it also details how the wheels of the wheelchairs get muddy and how having a device that could clean and dry the wheels would be highly beneficial. At the moment, schools often deal with this problem by cleaning wheelchair wheels by hand, but this is time consuming and takes away some of the children’s independence that staff and students work so hard to achieve.

Therefore, this type of product, if successful, could save time for the staff of Sherbourne Fields School and other schools and give the wheelchair users greater independence by allowing them to clean their wheelchairs without help. Also, various parts of society may also benefit from this device, such as by parks and National Trust areas.

It could improve the independence of wheelchair users and their enjoyment of outdoor activities. Furthermore, it may reduce the time it takes to clean wheelchair wheels so wheelchair users can continue with the rest of their day sooner. Therefore, according to the brief, it is important to consider that the device should clean and dry wheelchair wheels, as well as the mud guards. Also, the device should be easy to use and designed to allow the children and other wheelchair users to operate it themselves, where possible.

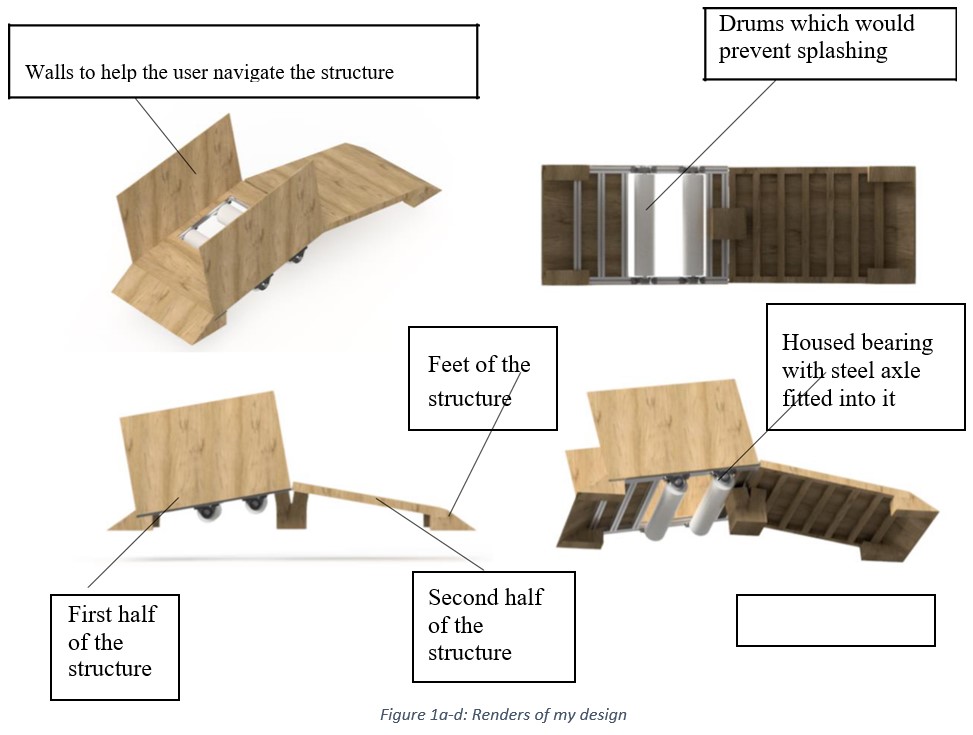

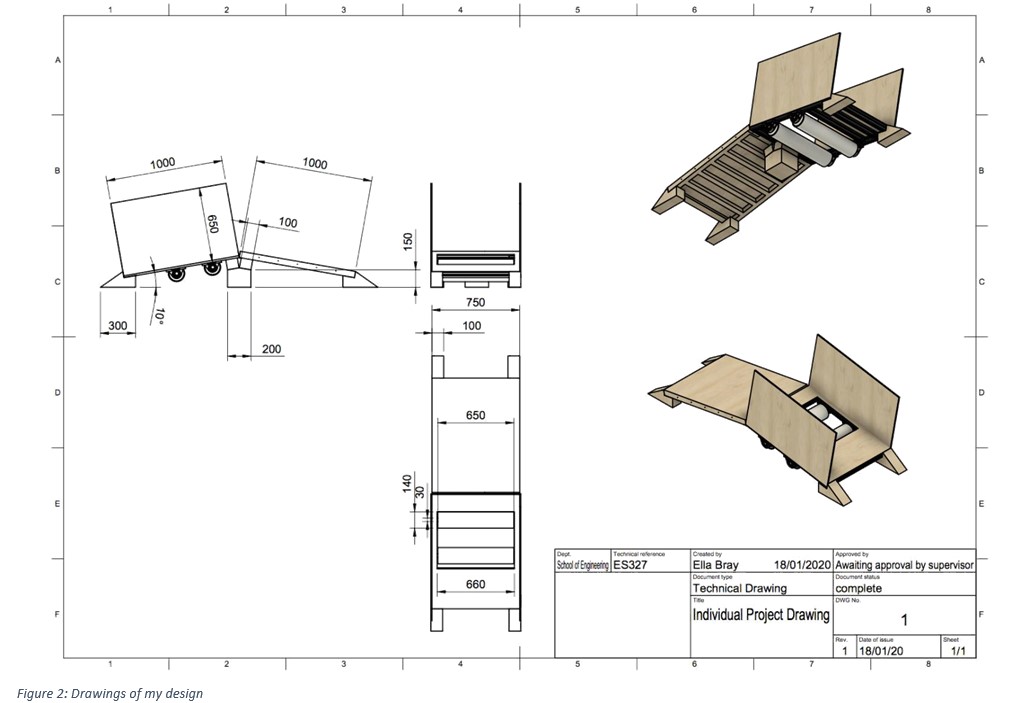

As shown in figure 1a-d, I created renders of my design using fusion 360. They were made for the manufacture of a prototype. A final product would have aluminium walls and sheets on top of the frames. It would also have flexi-brushes attached around the drums of the rolling road, a microfiber cloth attached to the second half of the structure, an 18.75mm diameter hole in each wall in between the drums for a hosepipe attachment, which can be used to supply water and two water collection trays, one underneath the rolling road to collect excess water and another with one with a moveable end which can be flat or held upright, placed under the ramp leading up to the first half of the structure.

Furthermore, a disk brake will be attached to the steel axle inside the drum at the raised end of the first half of the structure. The device is also foldable because the central support is made up of two separate halves and the two ramps are attached with hinges. This makes the device easier to store and more mobile.

With assistance, the user would drive their wheelchair up the ramp and onto the main structure. They would then drive onto the rolling road. Once here, the helper would turn on the water supply and the user would continue powering their wheelchair so that as the wheels turn, the drums of the rolling road also turn, cleaning the wheels. Then the helper should apply the disk brake by pressing the brake lever. The user can move the wheelchair off the rolling road and down the other side of the ramp, over the microfiber cloths which will dry the wheels. Drawings with dimensions are shown below in figure 2:

Through research three main existing products similar to this type of device have been found. The first is shown in figure 3. This device is made by INN2CARE. It works by the wheelchair user moving their wheelchair so that one of the wheels is in line with the device. Then they slowly drive onto it so the wheelchair wheel is turning on the brush. It claims to “easily and quickly remove dirt from the wheels, enabling people to drive indoors without leaving a dirt track print”. [5] Even if this is true,

which would adhere to the brief, the device could easily make a mess with the water it sprays over the wheels. It appears to be aimed at outside use, however if it is a wet day it would be much better if the device was designed for both indoor and outdoor use with some sort of water guard to prevent mess. Moreover, even though the device would clean the wheels it has no way of drying them so once the children go inside they will still create mess and it could be dangerous if their wheelchair wheels are slippery on the indoor flooring. In addition to this, the small device may be difficult for the children to navigate their wheelchairs onto themselves, which could potentially become a hazard or make the product less effective.

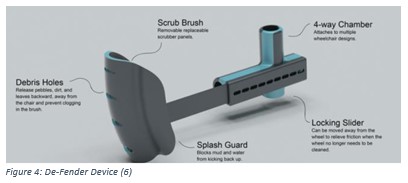

The price of the “Scrubber” is €298, [5] justifying that another aim for this project is to ensure that the price of my device is reduced to less than this to a more affordable price. Another competitor product is shown in figure 4. The device would be attached to a wheelchair wheel and then as the wheel turns it would brush against the scrub brush. It was designed by several researchers in America and is called De-Fender. [6] The main problem with this design is that it requires attaching to the wheelchair wheel, which means it cannot be used by children unassisted. This device also has no drying mechanism, again meaning that once the children go inside the floors will get wet and become a hazard. Lastly, the third competitor product is pictured in figure 5. It is called the NO-TRACS. [7] The user would drive their wheelchair to the top and turn the wheels whilst water is added, then they would drive off the other side of the ramp.

Although, this design would be easy for wheelchair users to navigate, like the first competitor (figure 3) it does not have a water guard or drying mechanism, meaning that wheelchairs can still make a mess and cause a hazard when they have left the device and water from the device is not prevented from splashing onto the floor during cleaning. In addition to the problems mentioned above, all of the competitor devices only clean the parts of the wheelchair wheels that touch the ground.

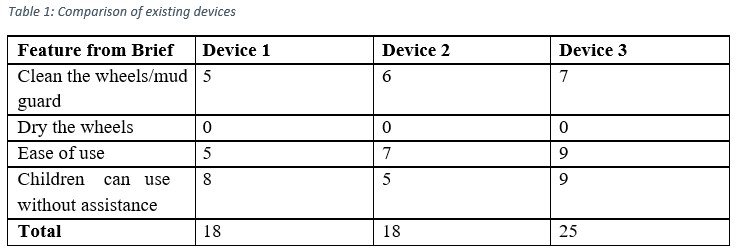

So, just the tyres are getting cleaned when in reality the whole framework of the wheels, including the mud guard, could be dirty. Henceforth, I looked into designing a device that can clean the whole wheel structure and not just the tyres, as well as one that has a drying mechanism and a way to prevent water making a mess outside the structure. Below is a table showing ratings of how well the existing products meet certain features discussed in the brief. The ratings are out of 10:

The highest-ranking competitor is competitor 3, shown in figure 5. It is a good design for allowing children to clean the wheels of their wheelchair, however, it does not have a drying mechanism or prevent splashing, which will occur from the water source spraying water on the wheels. Also, this design may have issues with removing waste water due to the section where the wheels are cleaned being flat. Moreover, it does not have the ability to clean the framework of the wheel or water guards. Therefore, these are aspects I have considered in my design

I would estimate a prototype with all the parts to cost £250-300. This is because I have already built a prototype with plywood instead of aluminium for the walls and sheets on the structures and without brushes, the water trays and a water source properly attached. This cost me £200 and from research I would predict that these extra items could cost £50-100 more as the trays could be bought for around £6 each from B&Q [8] and a hosepipe for around £15 also from B&Q, [9] however I am not fully sure how much brushes would cost, but a good supplier seems to be Mink Bürsten. [10]

1. Wallace, S. (2020). What does health and wellbeing mean in the context of disability?. [online] FutureLearn. Available at: https://www.futurelearn.com/courses/global-disability/0/steps/37586 [Accessed 23 Feb. 2020].

2. Canha, L., Simões, C., Gaspar Matos, M. and Owens, L. (2016). Well-being and health in adolescents with disabilities. Psicologia: Reflexão e Crítica, [online] 29(1). Available at: http://prc.springeropen.com/articles/10.1186/s41155-016-0041-9 [Accessed 18 Feb. 2020].

3. Epstein-Frisch, B. (2014). Promoting Independence for People with Disability. 1st ed. [ebook] NDIS. Available at: https://static1.squarespace.com/static/5898f042a5790ab2e0e2056c/t/5b1a0361562fa7 2ab73029c6/1528431463261/Promoting%2Bindependence%2Bfor%2Bpeople%2Bwi th%2Bdisability.pdf [Accessed 18 Feb. 2020].

4. Sutcliffe, P. (2019). SEN Magazine. [online] Senmagazine.co.uk. Available at: https://senmagazine.co.uk/home/articles/senarticles-2/who-needs-assistive-technology [Accessed 24 Sep. 2019].

5. Software.inn2care.com. (2019). Scrubber: Electric wheelchair wheel cleaner |

INN2CARE. [online] Available at: http://software.inn2care.com/?page_id=30 [Accessed 27 Sep. 2019].

6. Vitale, N. (2018). De-Fender: Wheelchair Wheel Cleaner. [online] Coroflot.

Available at: https://www.coroflot.com/noelvitale/De-Fender-Wheelchair-Wheel-Cleaner [Accessed 27 Sep. 2019].

7. Pulvermacher, R. and Lydon, B. (2019). NO-TRACS™ Automatic Wheelchair

Cleaner Keeps Floors Clean, Keeps Dirt and Germs from Entering Living Spaces. [online] PRWeb. Available at: https://www.prweb.com/releases/2008/09/prweb1323464.htm [Accessed 28 Sep. 2019].

8. Diy.com. (2020). Kaze Clear 50L Plastic XL Storage box | DIY at B&Q. [online] Available at: https://www.diy.com/departments/kaze-clear-50l-plastic-xl-storage-box/3663602763192_BQ.prd [Accessed 21 Feb. 2020].

9. Diy.com. (2020). Verve Hose pipe starter set (L)15 m | DIY at B&Q. [online] Available at: https://www.diy.com/departments/verve-hose-pipe-starter-set-l-15-m/1647807_BQ.prd [Accessed 21 Feb. 2020].

10. Mink-buersten.com. (2019). Mink Bürsten: Flex-System. [online] Available at: https://www.mink-buersten.com/no_cache/en/products-shop/strip-brushes/flex-system.html [Accessed 18 Feb. 2020].

When you submit your details, you'll be in safe hands. Our partners are National Accident Helpline (a brand of National Accident Law, a firm of personal injury solicitors regulated by the Solicitors Regulation Authority). They are the UK's leading personal injury service. Their friendly legal services advisers will call you to talk about your claim and give you free, no-obligation advice. National Accident Law may pay us a marketing fee for our services.

By submitting your personal data, you agree for your details to be sent to National Accident Law so they can contact you to discuss your claim.

If you win your case, your solicitor's success fee will be taken from the compensation you are awarded - up to a maximum of 25%. Your solicitor will discuss any fees before starting your case.

Our experts